By Cian Meier-Gast

Robotics is a constant struggle. You can work on a singular part of a robot for hours just to find out when you’re done that it won’t actually work and you have to take it apart again. The lab is pretty simple. Each team has their own cabinets with all of their parts and equipment in them. Tempers flare in the lab while working on the robot. The students get mad at the robot when it refuses to work and either scream at the robot or let out a frustrated sigh and walk out of the room.

There are some things that just refuse to work or be fixed. An example is Team 85B’s programming. Cameron Ling is the programmer and receives help from Matt Morrical’s dad, Andy. Ling and Mr. Morrical have spent countless practices trying to get a motor encoder to work. They kept having problems with whatever they wrote not actually working. Finally at practice on Nov. 2, Mr. Morrical was able to get the encoder to work. When asked what the problem was he said,“ I don’t know I just fiddled with it.”

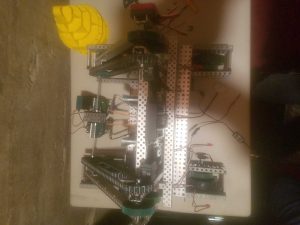

Christian Tanberg, a senior, said that there were some problems with the goal lift and that the team has had to redesign it a lot because the previous ideas didn’t work or took up too much space on the robot. Some of their ideas at the beginning were using a two bar lift to support the bottom lifter that went below and above the goal to lift it up. The problem with that was the motors weren’t strong enough to be able to lift the five pound goal. Even when they used rubber band assistants there wasn’t enough power to lift the goal. Another idea was using a rack and pinion system to lift the goal. The problems they had with that were that the rack and pinion got stuck and pieces of the robot and it was only able to raise about a half an inch of the ground when it needs to be to be lifted two inches off the ground. The newest idea for the lift was a rotator design that just rotates the holder of the goal up so it it can be rotated above the ground. The newest problems for that were that it doesn’t move equally and that it is still having a hard time to support it.

Morrical said that support is key so you need to three screw everything to make everything secured.

Team 85B has had a lot of problems with structural support. Some problems with supports was with the arm Tower. The tower would keep rocking and shifting back and forth making the robot unstable. It wasn’t fixed until the whole tower support was taken apart and redone adding more braces on the sides and having cross bracing did the tower become stable.

One of the last struggles that the team have faced is getting the claw arm to work. The problem that the team has with the arm is that it was very unstable and wouldn’t hold position when the arms stopped moving. Ling came up with an idea to fix the problem. He wanted to chain the front of the arms where the claw is to the back of the arms by the motor. This causes the arms to be steady but also still be able to rotate around the tower. This also fixed the problem of the arms not staying still when not moving. It held the arms in place when the motors weren’t being powered. The way the arms are the most stable though is having rubber band resistors. This makes it so that the rubber bands resist against gravity and hold the arms in place not letting them fall. The only problem with those are that the rubber bands will slowly degrade in strength until the bands snap from the stress.

Robotics is a constant struggle. There are always problems that need to be fixed and issues that will show up after you iron out an older problem. Nevertheless you can’t give up and you push on and prevail.